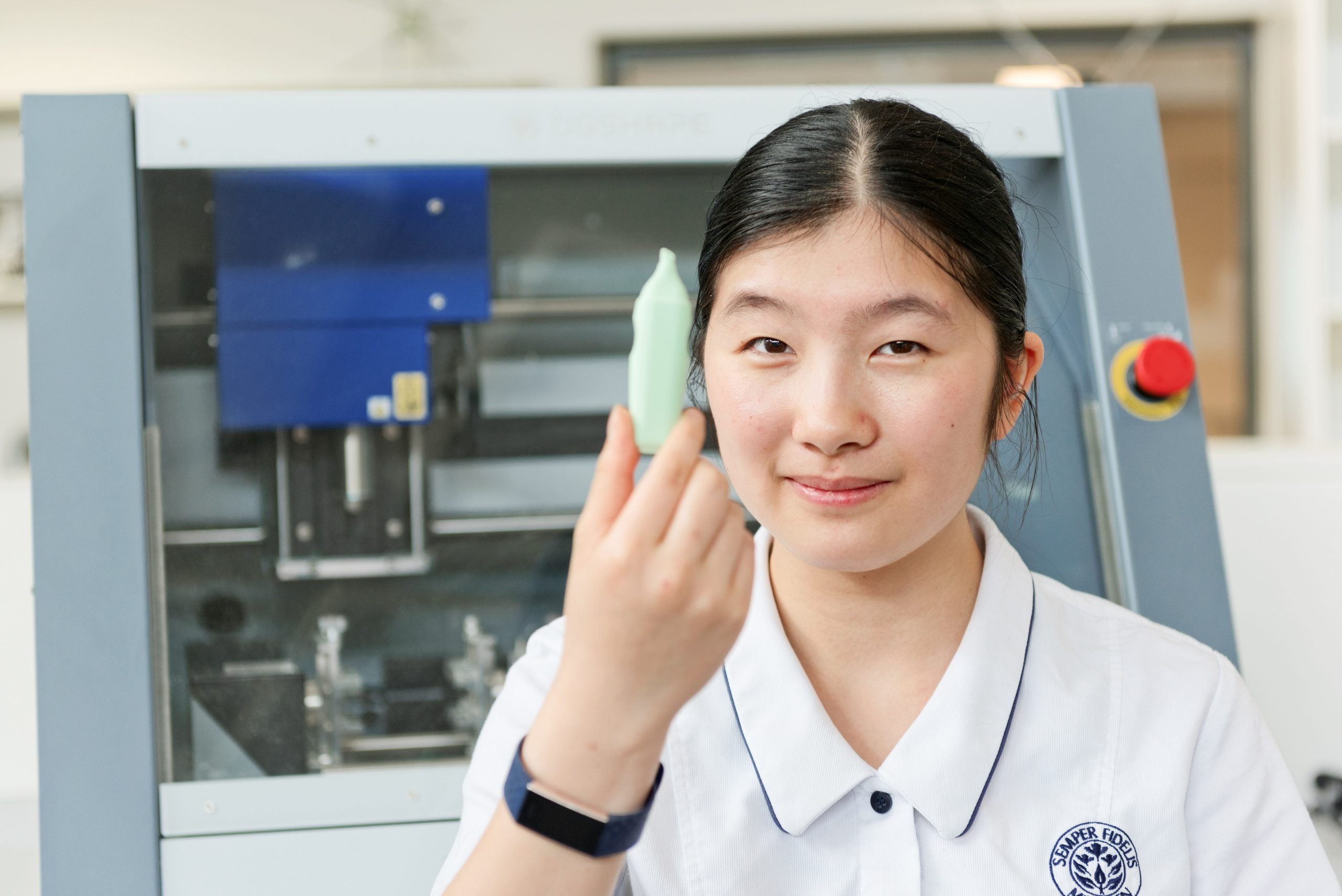

By the time a Meriden girl graduates, she has amassed many hours of practical experience with a range of STEM technologies, from coding to 3D-printing. In 2021, students will work with yet another high-tech device that will help future-proof their education with the addition of a Computer Numerical Control (CNC) machine to the School.

The CNC machine has been installed in The Foundry, a state-of-the-art learning space dedicated to STEM. The space is already equipped with two 3D printers as well as virtual reality, coding and robotics technologies.

CNC machines are essential tools in the industrial manufacturing process. They are designed to autonomously process material (wood, plastic, metal, glass or composite) to specifications set out by coded instruction. The code input into the machine controls the subtractive manufacturing process, that is, how the machine removes layers of the material to shape a custom-designed part or object.

Ms Ingrid Schwartz, Coordinator of Lateral Learning – STEM, said Meriden girls will be developing their industry-readiness by learning to use the machine through all stages of the manufacturing process.

“The students’ practical experience will begin at the first stage of the process, developing CAD and CAM designs and then feeding these into the CNC machine and monitoring the production,” she said.

“When the part is complete, the girls will test the integrity and function of their design and then improve the design as required. The process will hone their engineering and mathematics skills as well as their problem-solving abilities.”

This year, the CNC machine will be utilised by, among others, Year 10 students, who will be designing and manufacturing parts for solar-powered cars, and by Year 12 students, who will create components for their Design and Technology Major Works.

The School is thrilled to be able to continue to offer its students access to industry-standard technology so they can follow their passion for STEM and lead the way for women in the sector.